In competitive procurement environments, clarity and precision in vendor communication are essential. Among the many sourcing documents available, the RFQ (Request for Quotation) stands out as a structured approach for gathering cost proposals from suppliers.

Whether the goal is to procure materials in bulk or outsource standardized services, the RFQ process serves as a tactical tool to drive pricing transparency and accelerate decision-making.

Many businesses rely on RFQs to streamline their procurement cycles, reduce lead times, and ensure supplier accountability. Yet, despite its widespread use, confusion often arises over when and how to use an RFQ effectively.

Misuse can lead to supplier disengagement, pricing inconsistencies, or inadequate proposal responses.

This article will examine the RFQ in detail: what it means, when to use it, how to structure one, and its role in strategic sourcing.

Table of Contents

What Does RFQ Mean?

RFQ stands for Request for Quotation. It is a formal procurement document sent to selected suppliers, inviting them to submit price quotes for specific goods or services.

Unlike open-ended documents such as RFI (Request for Information), which seek knowledge, or RFP (Request for Proposal), which explore problem-solving approaches, the RFQ assumes the buyer already knows what they want.

| Factors | RFI | RFP | RFQ |

| Goal | Research | Problem | Precise Details |

| Suppliers | Both Qualified and Non-Qualified | Only Qualified | |

| Terms and Conditions | Negotiable or Non-Existing | Negotiable | Strict Criteria and Requirements of the Buyer |

An RFQ is highly structured and transactional. It includes detailed product specifications, quantities, delivery terms, and deadlines. The intent is to gather comparable bids based on uniform criteria, enabling cost-driven decisions without ambiguity.

In contrast to an RFP, which may request innovation, process methodology, or value-added services, an RFQ typically focuses on pricing for pre-defined solutions. It works best when requirements are stable, scope is fixed, and pricing is the dominant selection factor.

When issued correctly, the RFQ helps procurement teams avoid scope creep and ensures quotes are directly aligned with the business’s operational needs. It also reduces the administrative burden of clarifying inconsistent bids during the vendor selection phase.

When and Why Businesses Use RFQs

An RFQ is most appropriate when the required goods or services are well-defined and standardized. In these scenarios, pricing becomes the primary differentiator between suppliers, and the RFQ allows businesses to assess cost competitiveness at scale.

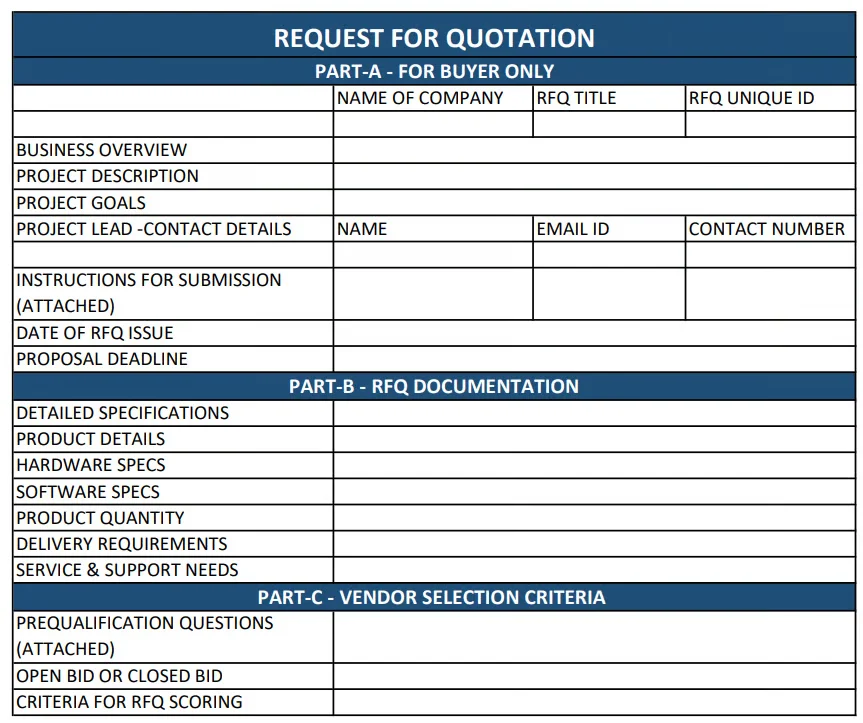

Example RFQ

RFQs are especially useful in industries with repetitive procurement cycles (such as manufacturing, logistics, retail, and construction), where specifications seldom change, and volume purchasing is routine.

For example, a manufacturing firm might issue RFQs quarterly to source raw materials like steel or copper from various suppliers under consistent terms.

Key drivers behind RFQ usage include the need to:

- Benchmark current supplier prices

- Establish competitive bidding processes

- Reduce maverick spending and contract leakage

- Enforce budgetary discipline through cost forecasting

That said, an RFQ is not universally suitable. It is ill-fitting when services are complex, custom-built, or require vendor expertise to define the scope. In such cases, an RFP or hybrid model is more appropriate.

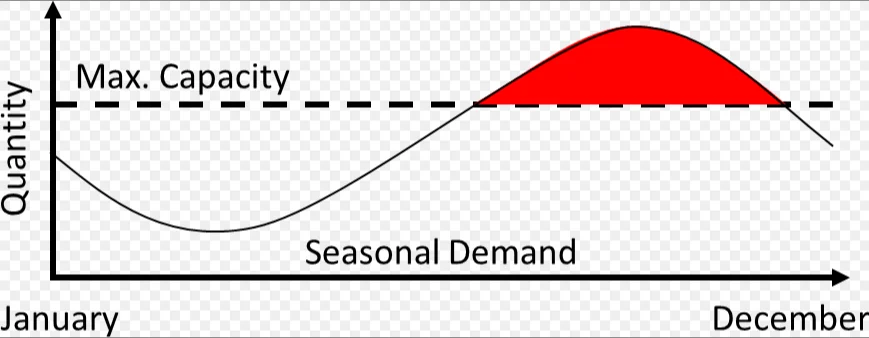

Strategically, RFQs offer operational speed. By eliminating subjective evaluation criteria and focusing on price and compliance, they shorten the time between supplier outreach and decision-making. It particularly benefits businesses managing seasonal demand spikes or urgent restocking cycles.

Ultimately, businesses use RFQs to negotiate better prices and enforce standardization, document compliance, and improve procurement traceability over time.

Key Elements of an Effective RFQ

An RFQ must be well-structured and comprehensive to deliver actionable and comparable quotes. Any lack of clarity or omission in the document may lead to supplier misinterpretation, inconsistent bids, or project delays.

Below are the essential components that should be present in every effective RFQ.

- Detailed Product or Service Description: Clearly specify what is being requested. This includes dimensions, materials, quantities, service scope, and any industry standards that apply.

- Submission Instructions and Deadline: Outline how suppliers should respond (via email, procurement portal, or PDF format) and by what date. Timelines should account for supplier review and internal approvals.

- Evaluation Criteria: Mention how the quotes will be assessed. Even if price is the main factor, include considerations like delivery timelines, warranty, or compliance with terms.

- Terms and Conditions: Include your company’s legal, payment, and delivery terms. It will establish a baseline of expectations and reduce post-selection disputes.

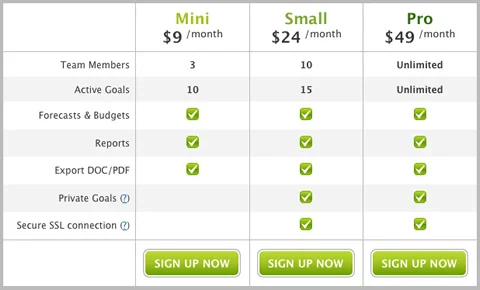

- Response Format Template: Provide a pricing table or quote structure to ensure consistency across submissions. This will make it easier to compare quotes side by side.

Pricing Table Example

- Contact Information for Clarifications: Assign a procurement or project contact to address supplier queries. This helps reduce assumptions and ensures all vendors operate from the same understanding.

- Company Background and Use Case: Briefly explain how the requested product or service fits into broader operations. Suppliers often provide better pricing when they understand scale and frequency.

- Confidentiality Clause (if needed): If sharing proprietary specs or volume forecasts, include a confidentiality statement to protect business interests.

Remember that a well-crafted RFQ speeds up the procurement timeline and enhances supplier engagement by reducing guesswork and improving bid quality.

RFQ Process: Step-by-Step Guide

An effective RFQ process follows a disciplined sequence to ensure pricing accuracy, transparency, and supplier alignment. Below is a structured approach to executing an RFQ from initiation to selection.

- Define Requirements Clearly: Begin by identifying the exact specifications, volumes, timelines, and delivery needs. Precision at this stage eliminates ambiguity in supplier responses.

- Create the RFQ Document: Compile the details into a formal RFQ, incorporating all essential elements: technical descriptions, submission guidelines, and evaluation methods.

- Identify and Shortlist Suppliers: Choose suppliers with a proven track record and relevant certifications. Limiting the list to qualified vendors can improve response quality.

- Distribute the RFQ: Depending on your sourcing strategy, send the document directly via procurement software or email. Set a realistic deadline for submission.

- Field Supplier Questions: Provide a single point of contact for clarification. Optionally, share all vendor questions and answers with all participants to ensure fairness.

- Receive and Evaluate Quotes: Collect all submissions by the deadline. Use a predefined scoring sheet to assess price, compliance, delivery capabilities, and additional terms.

- Negotiate (if needed): Engage shortlisted suppliers to clarify ambiguities or refine pricing. Keep discussions structured and documented.

How to negotiate with suppliers in procurement

- Award Contract and Notify Participants: Finalize the selection, notify both successful and unsuccessful vendors, and proceed to contract execution.

Benefits of Using RFQs in Procurement

Integrating RFQs into a procurement framework offers more than just cost visibility. It brings structure, efficiency, and accountability to the supplier selection process.

Below are four high-impact benefits that underscore why RFQs remain a cornerstone in strategic sourcing.

Price Benchmarking Across Vendors

An RFQ allows side-by-side comparison of supplier rates for the exact same deliverables. It enables accurate benchmarking and fosters price transparency without compromising quality expectations.

Standardization of Responses

By guiding suppliers to submit bids using a specific format, RFQs reduce variability in responses. This standardization simplifies evaluation and reduces analysis errors, especially in multi-vendor assessments.

Improved Supplier Accountability

RFQs establish a formal paper trail detailing what was requested and how the supplier responded. This becomes crucial when validating warranty claims, pricing commitments, or service terms during contract execution.

Shorter Procurement Cycles

RFQs are designed for speed, especially when compared to RFPs. Since the focus is on pricing for known specifications, decision timelines are significantly compressed, which is ideal for repeat purchases or commodity sourcing.

In essence, RFQs align procurement goals with operational efficiency. When applied correctly, they enhance supplier relationships while ensuring the organization remains agile in its sourcing decisions.

Common Mistakes to Avoid with RFQs

Even experienced procurement teams can encounter inefficiencies due to oversights in the RFQ process. Being mindful of the following pitfalls can improve both supplier response quality and sourcing outcomes.

- Issuing RFQs with vague or incomplete specifications

- Failing to set clear deadlines or submission instructions

- Overloading vendors with excessive background information

- Not defining evaluation criteria upfront

- Ignoring supplier feedback or clarification questions

- Treating RFQs as interchangeable with RFPs or informal price checks

- Using non-standardized formats that complicate comparison

- Skipping post-submission communication or feedback

Final Thoughts

RFQs are strategic instruments that shape vendor relationships, pricing efficiency, and procurement speed. When structured with precision and executed with discipline, RFQs help secure reliable partnerships and competitive quotes without bogging down internal teams.

For business owners, mastering the RFQ process means transforming procurement from a reactive cost center into a proactive value driver.

As market conditions evolve, the ability to request, evaluate, and act on vendor quotes with clarity becomes a competitive advantage worth refining. Make RFQs a standard practice in your procurement strategy.